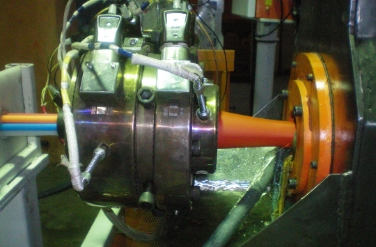

A-B-A Die head

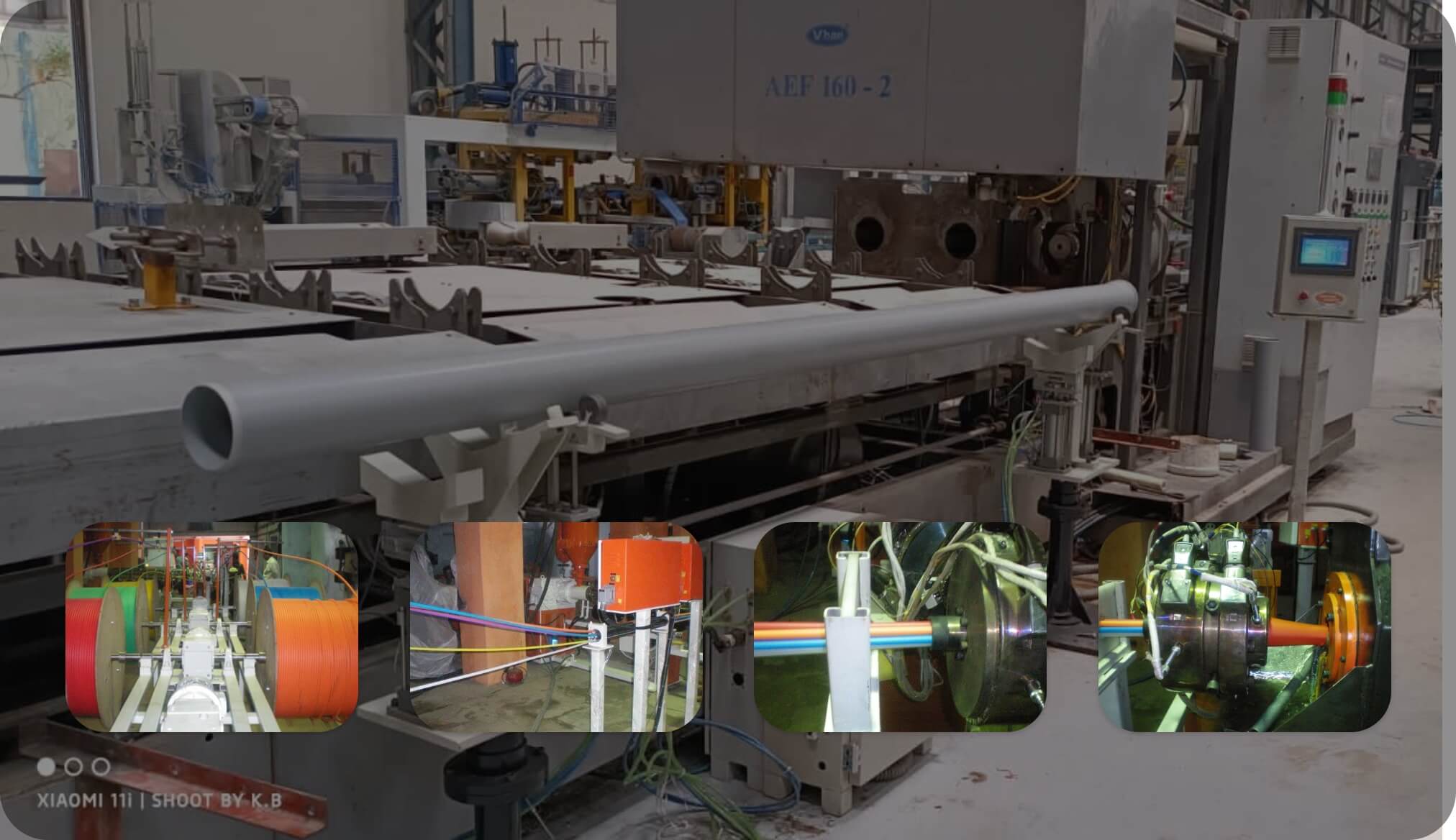

The latest innovation in irrigation technology ( DRIP and HDPE pipes ) is three layer pipes. These irrigation pipes are manufactured using a special 3 layer crosshead which extrudes an inner and outer layer separated by a core of different material.

The advantages of 3 layer pipes are cost savings and versatility.

- Three layer pipes can meet the technical standards of a high quality polymer single layer pipe with less cost by using an inexpensive core material.

- Three-layer pipe also provides greater versatility by allowing selection of layer materials to meet environmental and fluid handling challenges.

When manufacturing pipes for irrigation systems and water supply, a key consideration is how to keep your costs down while still producing a product that customers perceive as high quality.

One major cost is the material cost of the polymer used in making the pipe. Using a three layer crosshead allows you to use an inexpensive reground polymer for the core of the pipe (about 80% of the material) and thus cut material costs significantly while still maintaining quality. The remaining portion of the pipe, the 10% of the outside and the 10% of the inside ring, are made from a higher quality virgin material.

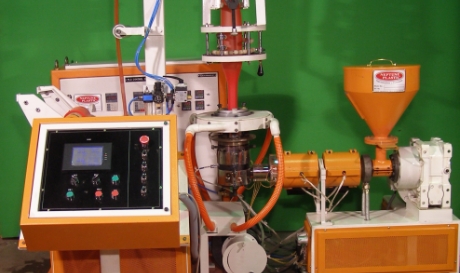

Models

| Pipe Diameter | Pipe Layer | Output Options |

|---|---|---|

| 20-110 | 20-63mm | 150 kg/hr |

| 20-110mm | 300 kg/hr, 500 kg/hr | |

| 63-250mm | 63-250mm | 500 kg/hr |

If you’re considering upgrading your plant’s pipe extrusion process, consider three-layer technology for your pipes. NEPTUNE supplies pipe extrusion machines that can be customized to meet your specific needs.

Applications