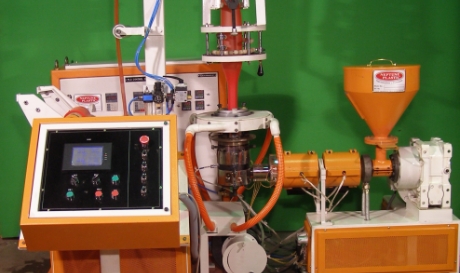

LAB EXTRUSION LINE

Lab extrusion is a small 2-3 kg/ hr Extrusion line designed to test and match colour shade to help masterbatch manufacturers. It saves on cost by taking trial run on this small extrusion line thereby saving raw material and power.

On one Extruder, you can test colour shade of Raffia Tape and Mono-filament. It is also used for skill development in educational and training institutes for students to have a practical hand on experience on operation of lines

Models

| Screw Diameter | Pipe Layer | Output Options |

|---|---|---|

| 25mm | Raffia Tape | 2-3 kg/hr |

| 25mm | Monofilament | 2-3 kg/hr |

| 25mm | Blown Film | 2-3 kg/hr |

Applications

-

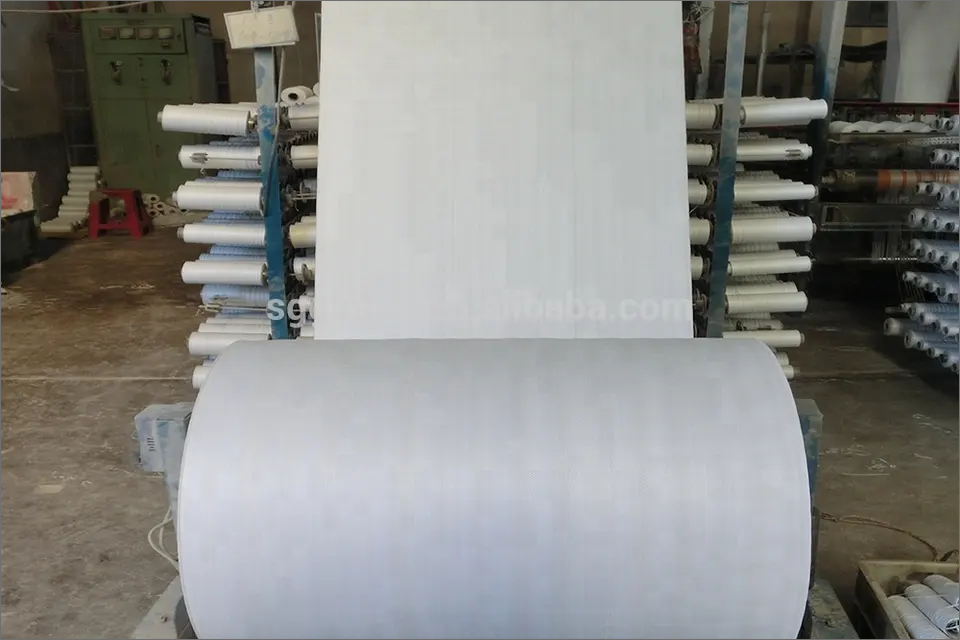

Raffia Tape

-

Monofilament

-

Blown film

Filament

Lab

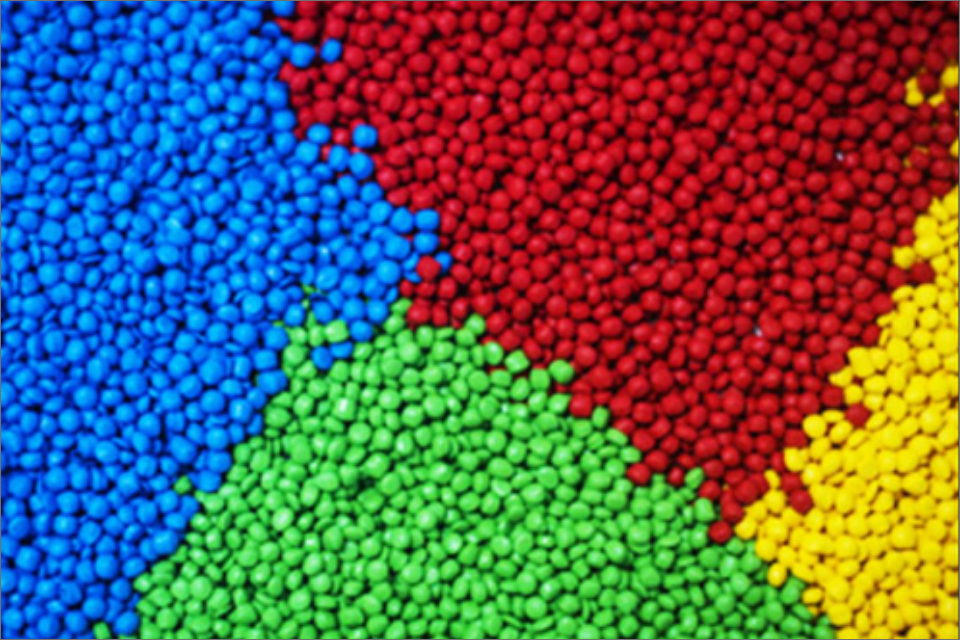

MASTERBATCH